An Engineering Insight authored by SK&A Associate Monika Crandall, PE, LEED AP. Follow Monika on Linked In.

Why Do We Need Relieving Angles?

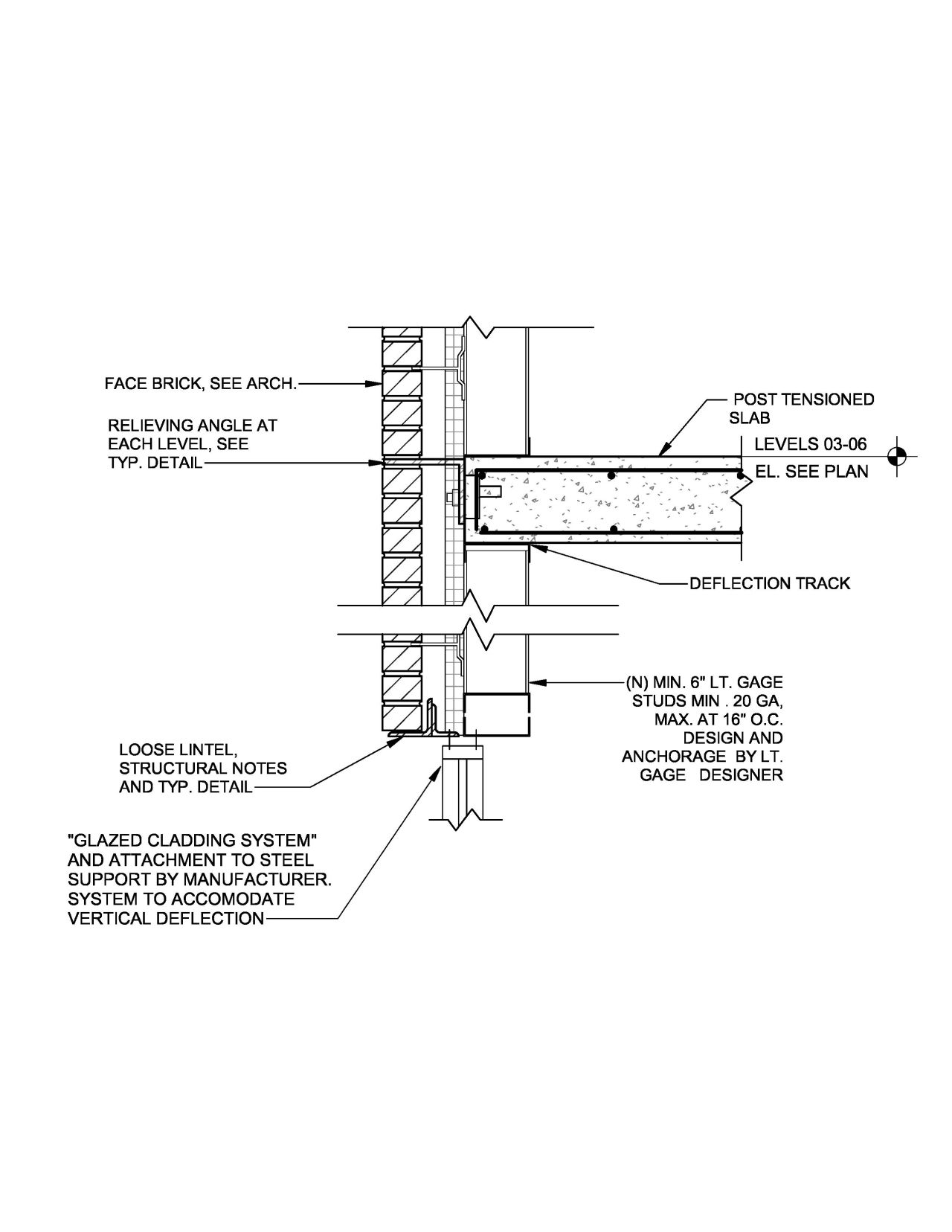

Relieving angles play a critical role in masonry veneer systems. Their main job is to transfer the weight of the face masonry back to the structure. This helps prevent overloading the veneer at the base, accommodates differential movement between the structure and cladding, and reduces cracking. Wood and light-gage stud backups are particularly sensitive to these issues.

Deflection Criteria Matter

Because masonry does not tolerate much movement before cracking, relieving angles need to be stiff. A common design standard is L/600 vertical deflection and 1/16″ torsional rotation.

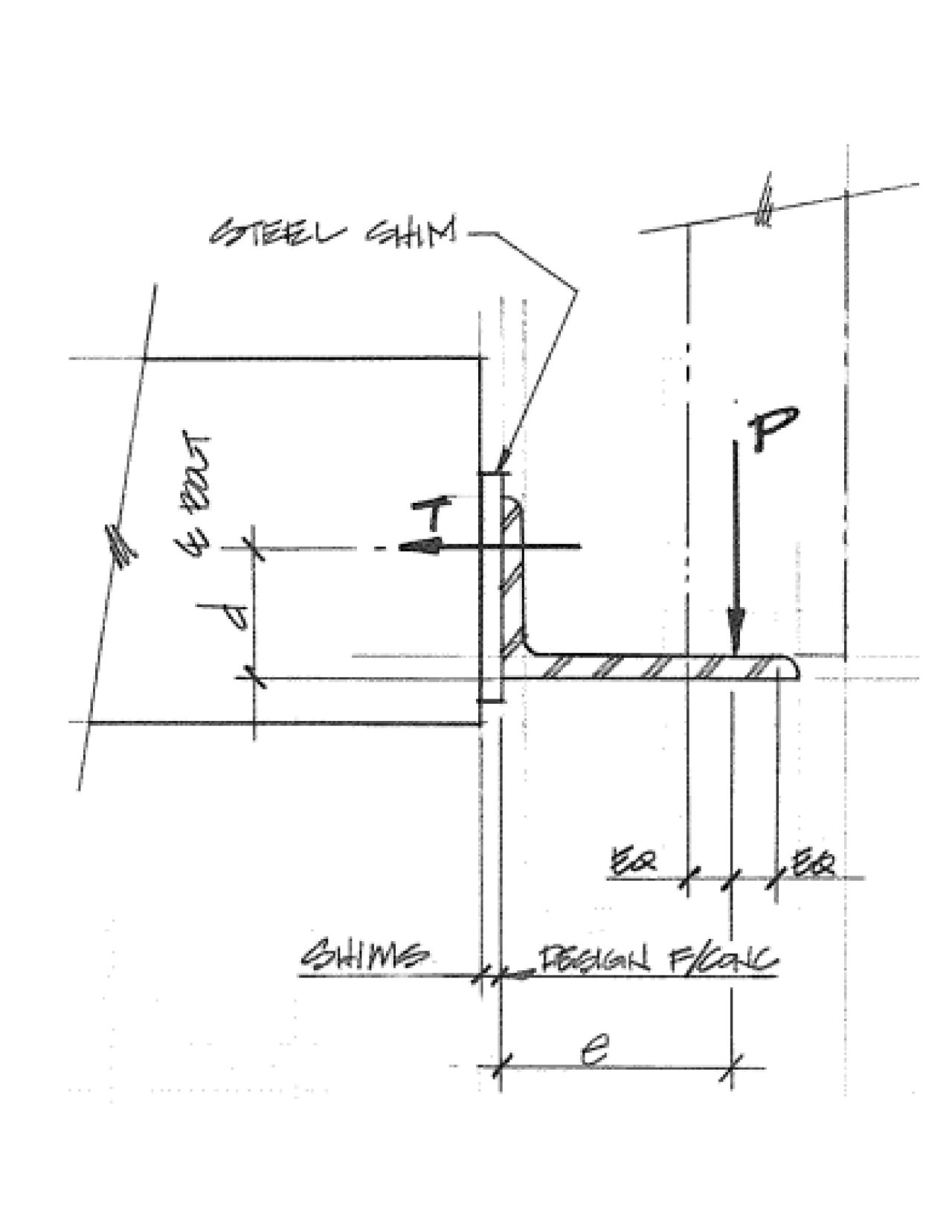

Sizing the Horizontal Leg

The horizontal leg of the angle should bear at least two-thirds of the veneer thickness. If the cavity is deep—as is increasingly common—you may need a bent plate to achieve proper support.

Construction Sequence & Adjustable Inserts

The angle must be installed and aligned before the masonry goes up. In the field, however, pour delays, embed errors, and other surprises are common. Adjustable concrete inserts and slotted connections make it possible to align the relieving angle on site without drilling or welding after the fact.

Differential Movement = Built-In Flexibility

Because the structure and veneer move differently over time, relieving angles must allow the masonry to “float.” The space beneath the angle allows for expansion and contraction of the masonry veneer, helping to prevent stress and cracking caused by thermal movement or other structural changes.

Common Field Issues

- Anchors set too high, too low, or buried in concrete

- Angles installed at different elevations across bays

- Shims missing or not fully bearing

- Movement joints omitted or sealed too tightly

When properly designed, installed, and adjusted, relieving angles help masonry veneers carry their weight, accommodate movement, and avoid cracking—while preventing many of the common field issues that can compromise performance.

This insight was originally published by Monika Crandall, PE, LEED AP, on Linked In. View the original post and add your own comments.