Authored by SK&A Principal Justin Long, PE, RBEC, BECxP. Follow Justin on Linked In.

Why Enclosure Failures Happen

Most enclosure failures aren’t caused by a single detail. They happen when moisture, air, thermal, & radiation control components and dynamic behaviors aren’t deliberately designed to work together as a performance system. This Enclosure Insights article will focus on SK&A’s systems approach to Building Enclosure Consulting.

Building Enclosure Consulting (BEC) helps project teams predict performance, prevent failures, reduce risk, and create durable, energy-efficient, comfortable buildings. At SK&A, we focus our design-phased services and technical reviews around five interconnected systems:

Moisture Control

- Bulk Water Infiltration: waterproofing & flashing components, drainage, transitions.

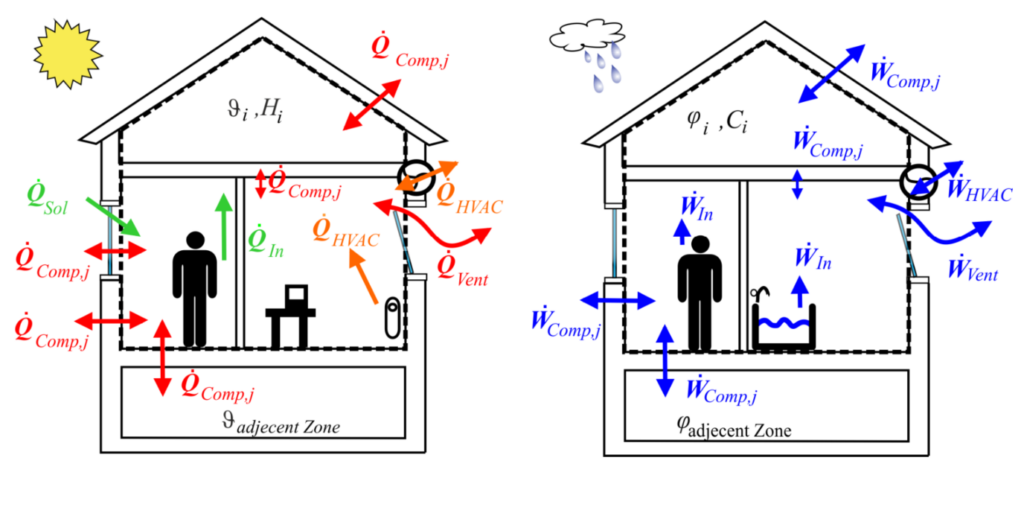

- Humidity: condensation, mold, and interior comfort.

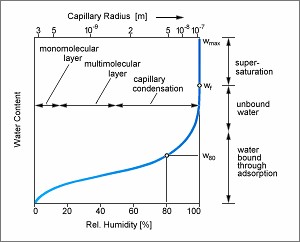

- Material Moisture: permeability, capillarity, drying potential.

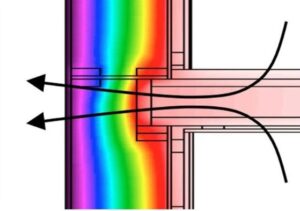

Air Control

- Airtightness: continuous air barrier + testing.

- Enthalpy Recovery Ventilation: heat + moisture recovery for balanced operation.

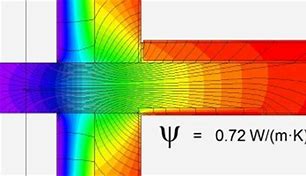

Thermal Control

- High-Performance Insulation: continuity + dew-point control.

- Thermal Bridge Elimination: slab edges, balconies, mullions, parapets.

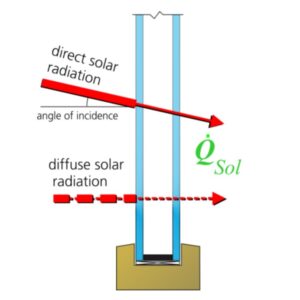

Radiation Control

- Radiation-Control Glazing: solar heat gain + comfort.

- Shading/Daylighting: overhangs, fins, and orientation-based strategies.

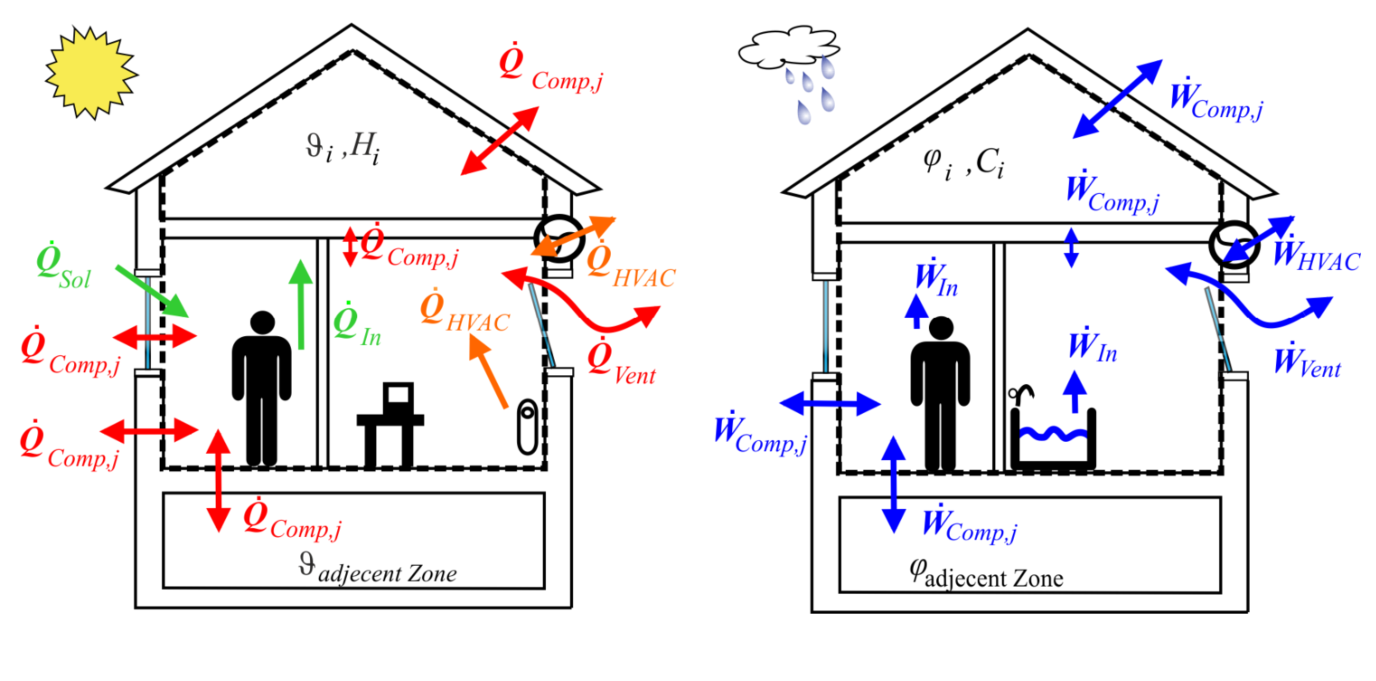

Dynamic Performance Control

- Hygrothermal Storage: how materials absorb/release heat + moisture.

- HVAC Dynamics: pressure, infiltration, and mechanical drying potential.

SK&A’s upcoming monthly Enclosure Insights will dive into each of these topics – helping designers, developers, and owners deliver predictable, long-lasting building performance.

SK&A’s Building Enclosure Consulting + Waterproofing team brings decades of experience and specialized technical expertise to aid in the design and construction of new buildings, as well as the evaluation and maintenance of existing buildings. Learn more.