An Engineering Insight authored by SK&A Principal Justin Long, PE, RBEC, BECxP. Follow Justin on Linked In.

Cold Weather Masonry Construction: What to Know as Temperatures Drop

As we enter the colder months, masonry construction requires additional planning and protection to maintain quality and long-term durability. Cold weather changes how mortar, grout, and masonry units behave — and without proper measures, it can lead to poor bond strength, reduced durability, and even freeze-related damage.

Code & Specification Requirements

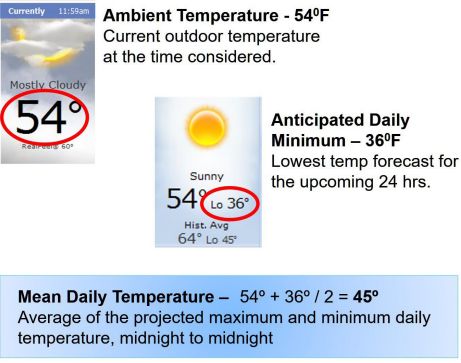

Under TMS 602 (Specification for Masonry Structures) and the International Building Code (IBC), cold weather provisions apply when ambient temperatures drop below 40°F (4.4°C).

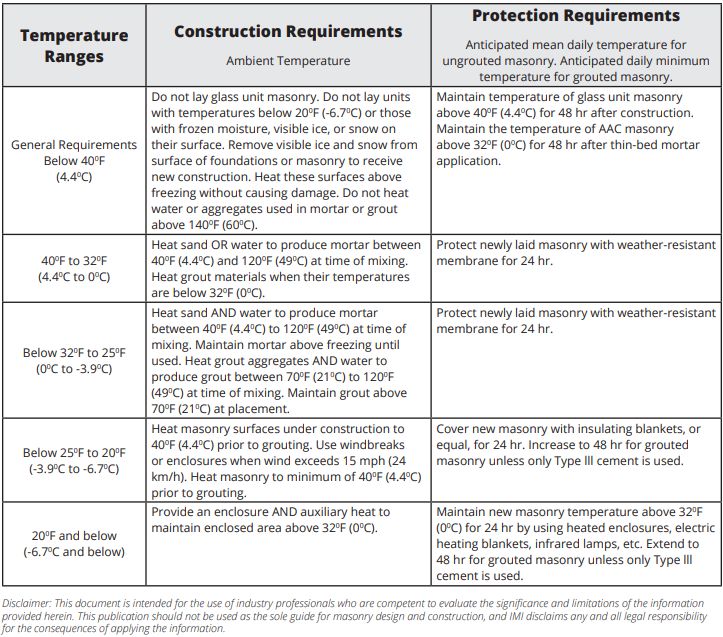

Key requirements include:

- Do not lay units containing ice, snow, or frozen moisture.

- Heat sand or water to ensure mortar temperatures stay between 40°F–120°F (4.4°C–48.9°C).

- Protect newly placed masonry for at least 24–48 hours, depending on temperature and grout type.

- When temperatures fall below 20°F (−6.7°C), use enclosures and supplemental heat to maintain air temperatures above freezing.

Practical Recommendations

- Preheat materials (especially sand and water) and store bagged cements and lime in enclosed, dry spaces.

- Avoid frozen substrates. Masonry must not be placed on icy or snow-covered foundations.

- Use heated enclosures or insulating blankets to retain warmth and promote cement hydration.

- Avoid calcium chloride accelerators — they can corrode embedded metals; use non-chloride accelerators if approved.

- Plan ahead. Coordinate schedules based on forecasted temperatures and provide contingency plans for extreme cold.

Why It Matters

The goal of cold-weather masonry construction is simple:

Ensure that cement hydration continues uninterrupted so that masonry achieves full strength and durability.

Freezing during curing can lead to weak, friable mortar, loss of bond, and premature deterioration — issues that can be easily prevented through proactive planning and compliance with TMS 602.

This insight was originally published by Justin Long, PE, RBEC, BECxP, on Linked In. View the original post and add your own comments.