NEWS + INSIGHTS

In the News

Our 2024 SE 2050 Embodied Carbon Action Plan

Awards

Marcia Camarda Wins Outstanding Achievement Award

In the News

SK&A Recognized for Diversity by the Washington Business Journal

Project Updates

Topping Out Hampden House

Staff Highlights

Celebrating Josue’s 5th Year at SK&A

Event

Happy Pi Day 2024

BY THE NUMBERS

800

MILLION + SQUARE FEET ENGINEERED

1960

THE YEAR WE BECAME A BUSINESS

38

REGISTERED ENGINEERS ON STAFF

27

STATES WE'RE LICENSED IN

OUR PROJECTS

Max Robinson Center

Washington, DC

The new Max Robinson Center is a 120,000 sf, six-story medical office building with one level of below grade parking totaling 26,000 sf. The building is located on Parcel 17 of the St. Elizabeths East mixed-use redevelopment, which includes over five million square feet of housing, retail, hotel, cultural, and office space situated over multiple parcels.

Carroll County Career & Technology Center

Westminster, MD

A specialized vocational high school, with over 850 students and 23 career-oriented programs. The project includes 108,000 sf of new construction and 83,000 sf of renovation.

Bethesda Place Plaza Renovation

Bethesda, MD

The Bethesda Place plaza had deteriorated and outdated finishes in need of revitalization and the various water leaks that affected the garage below prompted a full-fledged plaza renovation project.

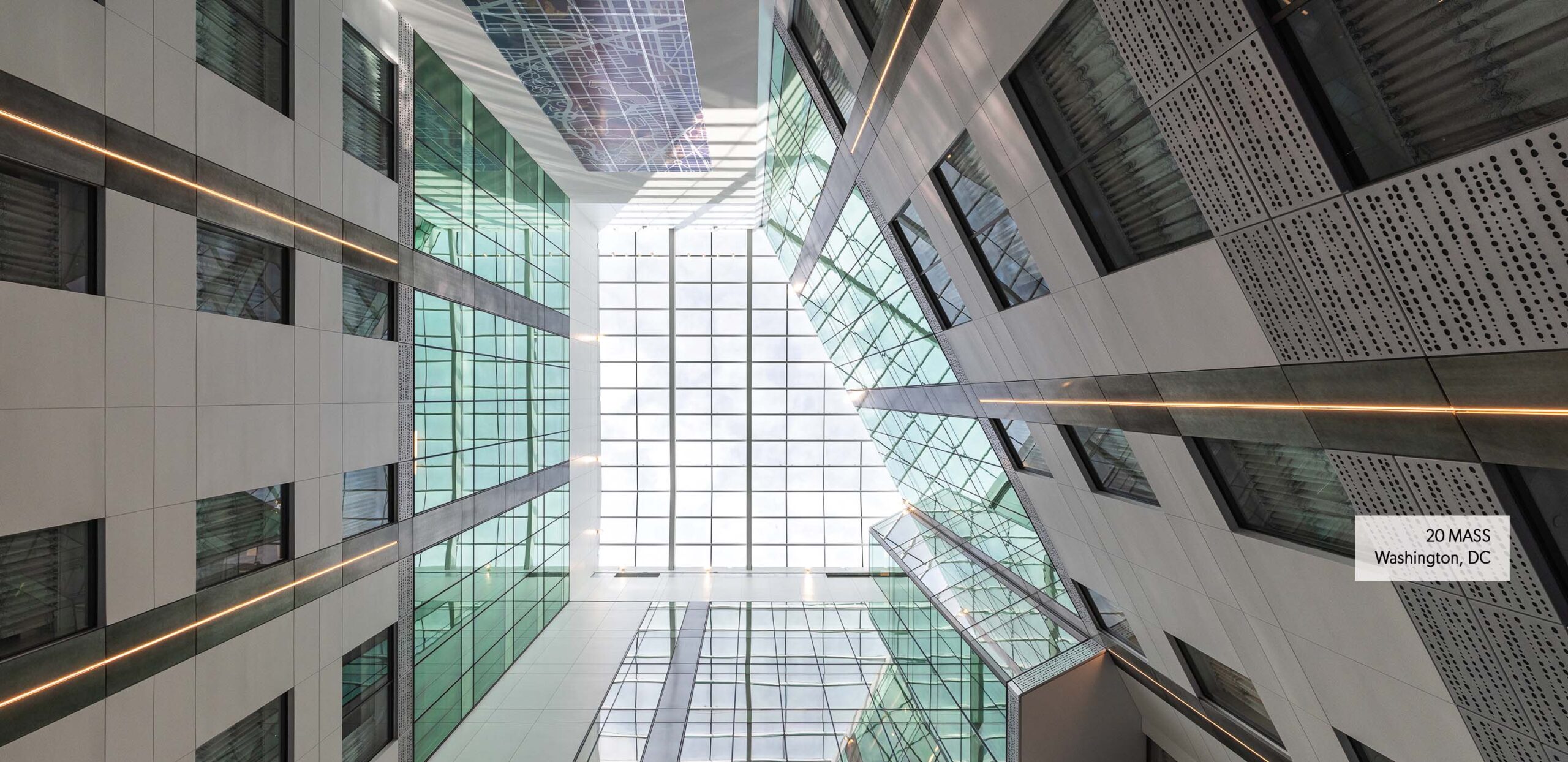

20 Mass

Washington, DC

Building upon the existing nine-story structure, the new 20 Mass building features three levels of vertical expansion and one bay of horizontal expansion.

Hart Auditorium Renovation

Washington, DC

Located in Georgetown University's Law Center, the 291-seat auditorium underwent a renovation program to update the facility’s lobby areas, reconfigure seating, and provide new AV and lighting systems.

National Landing Experience Center

Arlington, VA

The renovation of the National Landing Marketing Center required changing the use of the 6,200 sf space from business to assembly occupancy, which involved significant architectural and structural upgrades.

DC DGS Headquarters

Washington, DC

The new 258,000 sf facility features four levels of office space, ground floor retail, a penthouse, a rooftop terrace, and a below grade parking level.

Vela Connector Bridge

Washington, DC

An 11-story residential building with 379 apartments along with 16,000 sf of retail and co-working spaces. Spanning over one hundred feet, a specialized bridge structure supports the building’s primary amenity spaces for its tenants.

NoMaCNTR

Washington, DC

Located on the former site of a Greyhound bus terminal, the NoMaCNTR development features a new 13-story, 876,000 sf mixed-use building with a 235-room hotel and a residential component with 472 total units.

The Standard

College Park, MD

The Standard at College Park is a nine-story off-campus housing complex for students at the University of Maryland. The building features 282 units with 6,670 sf of ground floor retail along with other amentites.

670 and 680 Maine

Washington, DC

Located in DC’s Southwest Waterfront, 670 Maine and 680 Maine consist of two 11-story, Class “A” office buildings (480,000 sf), which are part of the phase two development at the Wharf DC.

Chemonics Headquarters

Washington, DC

The new Chemonics International headquarters is housed in an 11-story, Class “A” office building at The Yards mixed-use development.

Crystal Park Complex Garage Repairs

Arlington, VA

A comprehensive garage restoration program was designed, bid on, and executed with the work completed in phases while the buildings remained occupied and the garages partially open for use.

The Landing

Alexandria, VA

The Landing is a boutique-style senior living rental community tailored to help residents thrive with individualized wellness programs including assisted living, independent living, and memory care.

Tucker Road Ice Rink

Fort Washington, MD

SK&A served as the Building Enclosure Commissioning Authority (BECxA) and provided Building Enclosure Commissioning (BECx) services for the Tucker Road Ice Rink.